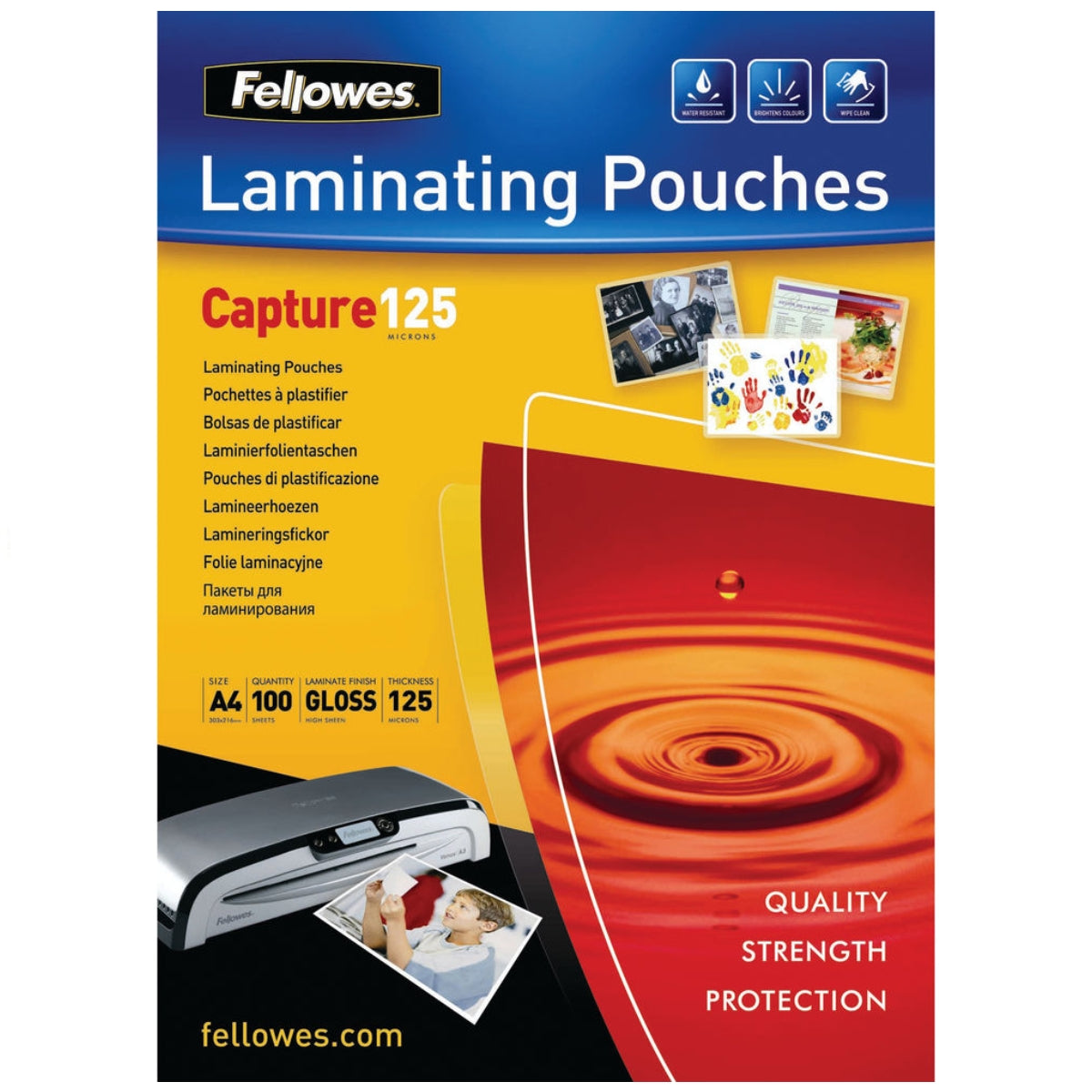

Fellowes A3 Laminating Pouches Capture125

- A3 - 303 x 426 mm

- 125 Microns

- 100/pack

As you aware that the Fellowes manufacture the best Laminating pouch in the world and the reason for this is:

1. Fellowes are the only brand to uniquely offer 3 layer pouches:

- PET - Polyethylene Terephthalate

- LDPE - Low Density Polyethylene

- EVA - Ethylene Vinyl Acetate

Therefore you can be sure when you are using Fellowes pouches of a quality lamination.

2. Fellowes pouches use the highest quality materials from sources in Taiwan and Korea only. All unbranded and some branded competitor pouches use lower grade Chinese materials.

3. This 3 layer spec offers a reliable pouch and prevents one of the main causes of jamming in laminators which is excess glue (EVA) on the rollers. This is because the LDPE is absorbed into the PET during the laminating process and therefore less chance of excess glue going onto the roller and jamming the machine.

4. The opaqueness of the pouches prior to being laminated is a key difference and one where you can easily tell whether you have a Fellowes pouch. The opaqueness of the pouch is dependent on the meshes on the cooling roller. Higher mesh provides a clearer appearance, whereas less mesh provides an opaque appearance. Most pouch suppliers to other competitors use 200 meshes on the cooling roller whereas Fellowes pouches use only 175 meshes which provide a more even and better coating finish.

5. The clarity of the pouch after lamination of an alternative quality branded 2 layer pouch and Fellowes 3 layer pouch is identical. Therefore the benefit of our pouch against our quality branded competition is to prevent jamming.

6. However, nearly all unbranded pouches are 2 layer and the majority of these are of irregular composition. Some very cheap branded pouches also use an irregular composition. By irregular composition we mean that the percentage of PET is less than the percentage of EVA. For example, a 125mic pouch with perhaps 50mic PET + 75mic EVA coating is considered irregular composition. Irregular composition of unbranded pouches is the main reason why EVA leaks out onto the rollers and why machines jam.

7. New Quality Packaging to improve consumer awareness of the brand and loyalty to re-buy the brand to improve growth in sales for our customers.